Computer-Aided Design or CAD services are broad, complex, and several industrial uses to fulfil their different requirements. CAD software is not only limited to creating 2d drawings or creating a design perspective — the applications are myriad.

From automotive to architecture, construction, and aerospace, engineers use CAD design and drafting services to accomplish complex designs and innovations. It’s among the most versatile software that individuals can use to turn their idea into an executable and practical design. On this note, look at some of the CAD services in multiple industries making industrial conceptualizing work streamline.

2d CAD design

The majority of engineers prefer to create their 2d design on CAD for higher accuracy and re-usability. Using software like AutoCAD or SolidWorks, engineers can draft intricate 2d designs. These designs are later sent to machines to manufacture custom-design products or to cut materials. These 2d CAD designs are also crucial in incorporating more significant drafts into parts with higher accuracy.

2d drafting

2d drafting is among the widely-employed CAD applications, which uplifts the overall efficiency of designers to prepare drafts in a shorter turnaround time. With 2d drafting, it’s easier to store detailed information and data related to a design. It’s widely used in the initial stages of product design work.

CAD assembly drawings

Mechanical parts consist of multiple intricate components, and assembling them is a time-consuming and complex task. To understand every piece and the way of assembly, engineers need an assembly drawing. This CAD drawing helps technicians understand how all parts will fit together to form the complete equipment.

CAD Digitalization

Several companies across industries use traditional drawing methods for CAD modelling, and it comes with several shortcomings. Along with not making quick changes, these paper designs are prone to damage by several external factors. To preserve and keep the drafts safe, engineers use CAD digitization services to scan the paper-based procedures and convert them into digital files. By transferring designs, it becomes easier for engineers to work and implement new changes.

CAD electrical drafting

Electric CAD design services are among the high-demand services, and this drafting is used to design electrical systems and assemblies. These are very intricate drawings that consist of comprehensive information about the complete electrical setup or a plant. The electrical systems are complex, and to make the actual implementation easier, technicians distribute the architecture. With electrical CAD files, engineers can understand all details in less time.

CAD fabrication drawing

CAD fabrication drawings and 3d CAD models are widely popular in the construction and manufacturing industries. These drawings show how engineers will construct, fabricate, and build a specific structure. Some of the common examples of such drafts are steel reinforcement, building foundations and more. Architects can quickly draft different project drawings to understand how the architecture will look once it’s complete.

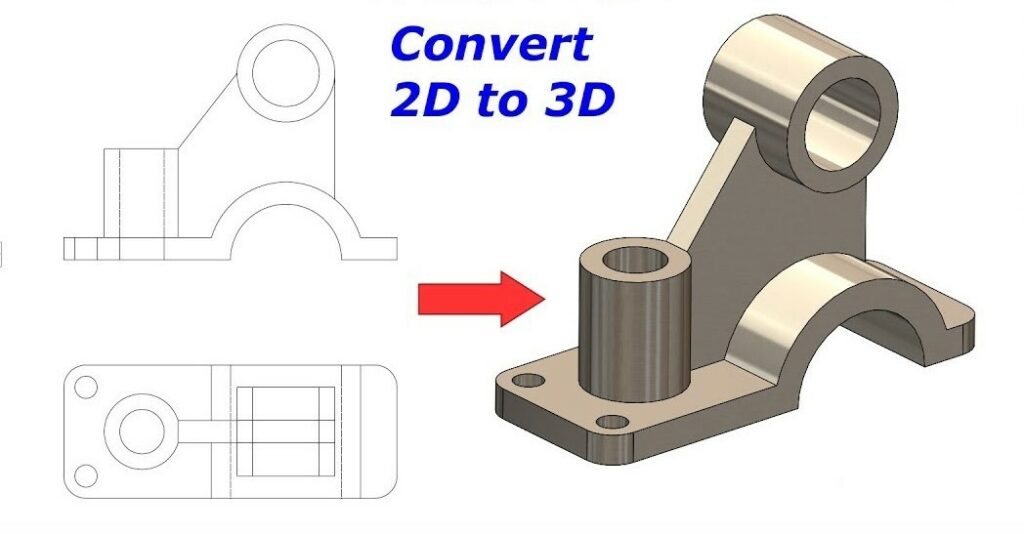

2d to 3d Drawing

All complex design starts with basic 2D drawings, and these 2d designs show different views of equipment or a structure. However, to compile more information like tolerance levels, materials details, and accurate measurements, specialists create 3d models. In this process, engineers take multiple 2d drawings and convert them into full-fledged 3d models. In 2d to 3d comparison, designers can render the design with custom textures, lightings, shading, and more.

3d CAD design is easier to reuse and modify as compared to the traditional 2d drawings. With 3d modelling, engineers can visualize the complete structure and analyze it for various external factors. It makes the 3d designs more efficient, time-saving, and understandable. Below are some of the primary benefits why designers should shift from 2d designs to 3d modelling:

Faster product design

The major difference between 2d and 3d drawing is work efficiency and speed. Compared to the 2d designs, 3d designs are more flexible and easier to handle, and it’s ideal for faster design prototyping while working with a team. The design communication with customers or team members becomes seamless using 3d CAD models. Technicians can analyse all the real-life use cases and improvise the design without drawing it again from scratch.

Rendering and animation

Companies should take advantage of CAD outsourcing services as 3d modelling allows them to render the design architecture with various animations and perspectives. This thing is not possible in the 3d design, and it makes the visualization process slower. To overcome this problem, 3d CAD creates a more efficient external and internal view of a design. Along with this, 3d designs are multi-purpose, and marketing teams can use them to promote the product on the go. Industries like automotive, construction can use 3d models to demonstrate their upcoming innovation in an information-rich manner.

Simulation and testing

Design simulation is a vital part as it helps designers to understand the design behavior in real-world scenarios. Engineers can simulate, test and validate their design to identify flaws and reduce the overall manufacturing cost. These virtual prototypes slash the need of having physical structures for simulation. Technicians can run multiple tests on the same 3d CAD file, which saves both time and effort. The complete design simulation becomes seamless with 3d models.

Easier data management

Another primary reason behind shifting from 2d design to 3d models is efficient data management. As the project or team grows over time, the design complexity also increases. When the drafts are in 2d format, there are several factors that engineers need to keep in mind while using them. However, when all data is in digital 3d format, the model is easier to modify, store or share with others. With 3d CAD, companies can standardize their design process across all their work network. It will help them achieve a more streamlined work procedure.

Automation of design process

Automating the design process can increase the speed and accuracy of output. Even non-technical individuals can leverage the automation feature to generate 2d and 3d drawing from a 3d model and reuse them when needed. This flexibility is only achievable while working with 3d models as the 2d designs are paper-based and can’t be reused.

These were some of the CAD services and advantages of shifting from 2d to 3d CAD modelling. Regardless of industry and company size, 3d CAD modelling brings in more flexibility and cost-effectiveness to business. If you are not taking advantage of it, it’s the right time to switch and optimize the design communication process.